PDC and Tricone Bits

PDC bits (from English Polycrystalline Diamond Compact bits) are special types of drill bits primarily used in the oil and gas industry for drilling into hard rock. They are characterized by the use of synthetic polycrystalline diamond as the cutting material, which is extremely hard and wear-resistant. Today, they are also widely used in other drilling areas such as well drilling, geothermal energy, and foundation engineering.

Main features of PDC bits:

- Cutting part: Consists of PDC “cutters” made from a layer of polycrystalline diamond bonded to tungsten carbide. These cutters are brazed on to a steel or matrix body of the bit.

- High efficiency: Due to the hardness of the diamond, PDC bits are highly efficient in drilling, as they retain sharpness longer and handle high drilling speeds.

- Usage: Most commonly used in soft to medium-hard formations, but with technological advancements they are also applied in harder formations.

- Advantages:

- Longer lifetime compared to traditional bits

- Higher drilling speed (ROP – rate of penetration)

- Lower bit costs per meter

- Less round trips for bit change = higher efficiency

Currently produced types of PDC bits in our production:

- PDC with welded wings

- PDC with changeable wings

- PDC with steel body

- RC PDC with steel body

Different qualities of PDC cutters are possible Standard: most used, Premium: for harder formation and Oilfield quality for very hard formation

Types by design:

-

The PDC with welded wings could be with 3, 4 or 5 wings. The side caliber of the wings are min 80mm and could be with TCI or PDC inserts. Extra wear protection is also possible on request. Threaded connections are turned according to customers requirements. Chisel diameter according to customers requirements.

-

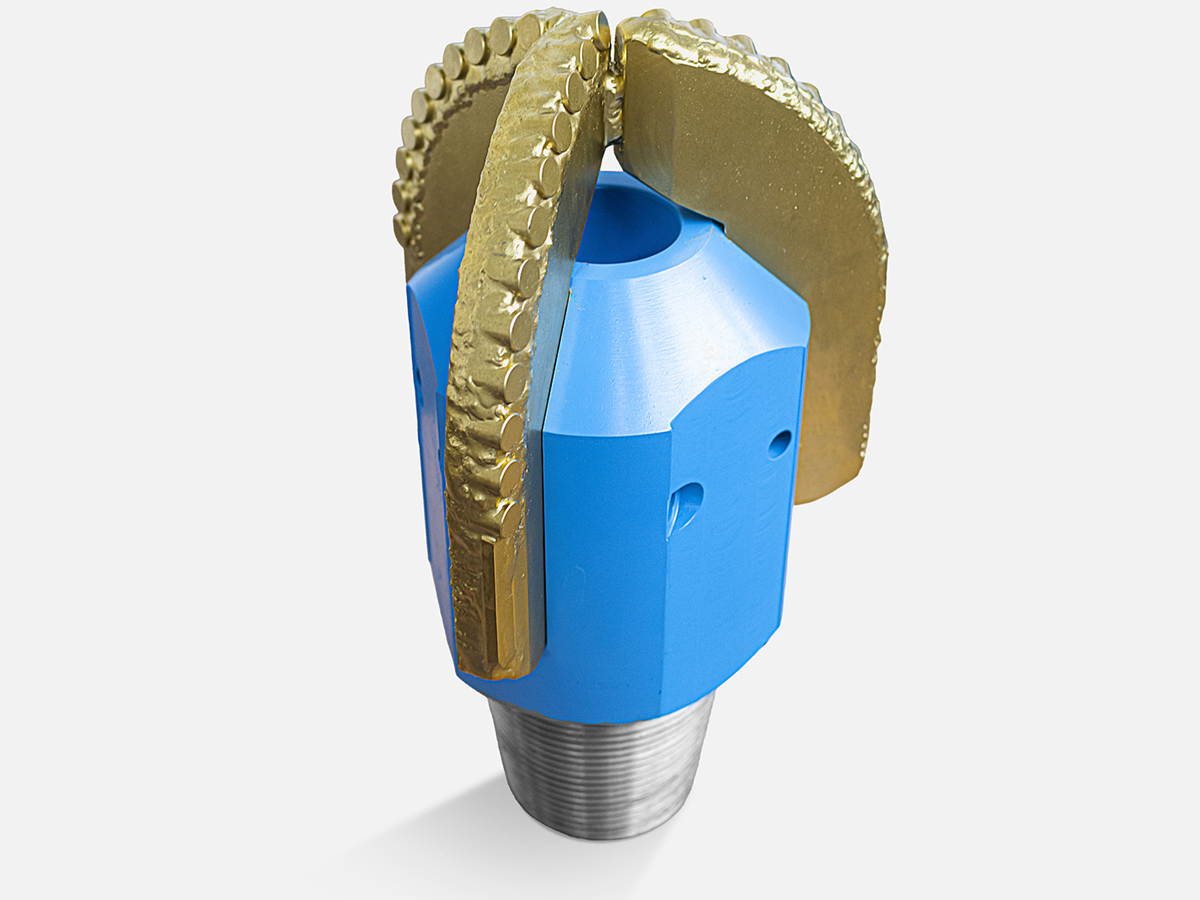

PDC with interchangeable wings is a product we have developed to further reduce bit costs for diameters from 190mm. This means that the customer only needs to purchase the blades for the different diameters, while the base body remains the same. The Wings have also long caliber and are hard faced. Threaded connections are turned according to customers requirements.

-

Bit diameter according to customers requirements PDCs with steel bodies are manufactured from a single piece in 3 or 5 blade designs.

Threaded connections are manufactured according to customers specifications. Available diameters: 127 / 134 / 140 / 152 / 165mm In single-row and double-row versions available. -

RC PDC bits were specifically developed by EDC for larger diameter airlift drilling. These bits, with 3 or 5 blades, can be used for both systems: direct flushing and airlift drilling. The blades are also hard faced.

Available diameters: 190, 216, 241, 270, 290, 311, and 330 mm Larger diameters available upon request.